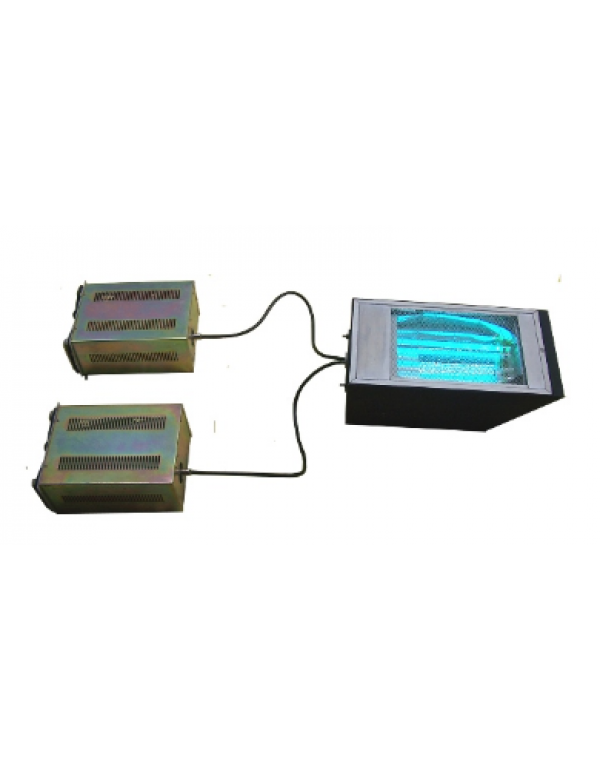

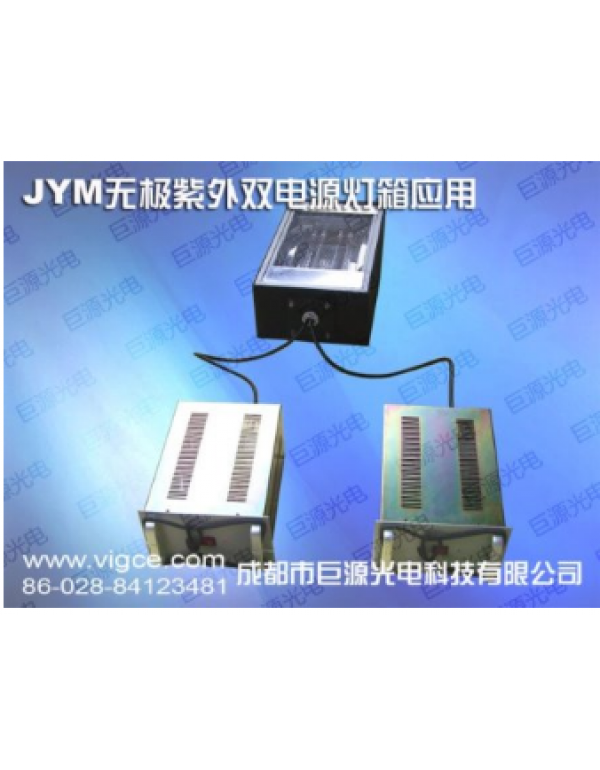

Jym-3000 UV cleaning equipment

Light cleaning equipment

Material surface cleaning

Material surface modification

UV oxidation reaction

Product Description: using short wavelength UV surface cleaning and surface modification technology, using clean high-energy UV light source, the material can be treated to obtain extremely clean surface and strong surface adhesion. The basic reaction of modification is the oxidation reaction caused by UV. After UV irradiation on the solid surface, the pollutants on the surface are oxidized, then decomposed into volatile substances such as CO2 and H2O, and finally evaporated. Moreover, hydrophilic atomic groups such as Oh, COO, Co, COOH and so on are formed on the surface, and the surface adhesion of the modified surface is improved by leaps and bounds.

Product Description:

Some materials used in general industries or high-tech fields have very high performance and are very friendly to the environment, but the continuity and printability of these materials are generally very poor. The short wavelength ultraviolet (UV) surface cleaning and surface modification technology provided by the company can obtain extremely clean surface and strong surface adhesion after the above materials are treated with clean high-energy UV light source.

The basic reaction of modification is the oxidation reaction caused by UV. After UV irradiation on the solid surface, the pollutants on the surface are oxidized, then decomposed into volatile substances such as CO2 and H2O, and finally evaporated. Moreover, hydrophilic atomic groups such as Oh, COO, Co, COOH and so on are formed on the surface, and the surface adhesion of the modified surface is improved by leaps and bounds.

The progress of UV light source technology ensures that UV / O3 surface modification technology gives full play to its outstanding advantages. UV / O3 surface modification technology has been widely used in solid surface treatment because of its high cleanliness and surface adhesion.

Features of UV cleaning:

The treatment in the atmosphere is simple, convenient, environmental friendly, without secondary pollution, without heating, liquid medicine and other treatment.

The cleanliness is very high, below the single molecular layer, which can obtain unimaginable continuity of previous treatment methods.

The unique ultra-high output and short wavelength ultraviolet light source in China can give full play to the powerful processing capacity and significantly improve the production efficiency with only a short time (second unit) of irradiation.

It is effective for most plastic products and has wide applicability.

Large consumption of liquid medicine and heat energy can be avoided, and the operation cost is low.

Application scope of UV cleaning technology:

The optical cleaning method is most suitable for the production of liquid crystal display devices, semiconductor silicon chips, integrated circuits, high-precision printed circuit boards, optical devices, quartz crystals, sealing technology, metal materials with oxide film, etc.

Main materials: ITO glass, optical glass, chrome plate, mask plate, polished quartz crystal, silicon wafer and metal with oxide film, etc.

Can remove dirt: organic dirt, human body sebum, cosmetics grease, resin additives and polyimide, paraffin, rosin, lubricating oil, residual photoresist, etc.

This UV light source has the characteristics of UV modification (UV surface quality change) in LCD technology. At present, it is mainly used in film processing technology in the production process of LCD STN, which is very effective for improving the tight connection between film and film, such as ITO film and photoreceptor film, top coating and PI coating, etc. In addition, in the research department, it can also be used for UV modified plastic material products and nanotechnology research. The chemical reaction of the products after UV irradiation changes the surface properties of the products.